About 200 years ago, the steel shed replaced wooden buildings as the preferred outbuilding solution. In modern times, the Fabric Shelter is to the steel shed what the steel shed once was to the wooden building; a compelling disruptor that performs in areas where steel buildings lack.

Also referred to as Shipping Container Workshops or Container Shelters, Fabric Shelters have become the new preferred warehouse or workshop solution for many of the world’s leading mining and industrial companies. They are a clever alternative to the traditional steel shed option, offering unique benefits that have made them a well-established Shelter Solution around the world.

The Shipping Container Workshop is so named due to the use of standard sea containers as a mounting system for the steel and fabric arched roof structure. Mounting on sea containers, which are easily available anywhere in the world, means the only aspect of the shelter that needs fabrication and transport is the roof structure and end walls if required.

Why choose a Shipping Container Workshop

There are a range of reasons to choose Shipping Container Workshops for your project or workshop – 5 key reasons are listed below.

1. Cost

When CSBP, a long-time client of DomeShelter Australia, required eleven large Shelters for storage at their Kwinana depot in Perth, they compared the cost of Fabric Structures to the equivalent coverage by steel sheds. According to the client, the cost of a DomeShelter Solution was cheaper by an “order of magnitude”.

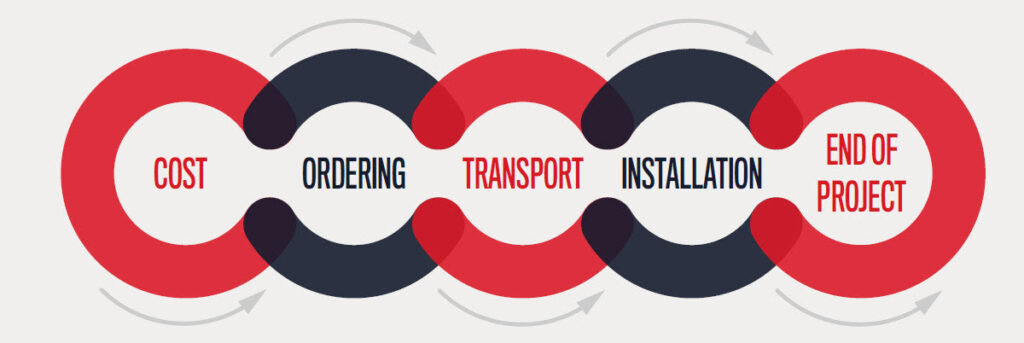

Capital procurement demands a thorough analysis of the lifetime cost of buying an asset, or Total Cost of Ownership (TOC). This accounts for all costs, from the original purchase, transport to site, installation, on-going maintenance and dismantling at the end of the project. Shorter installation times, minimal maintenance and the relocatable nature of Shipping Container Workshops lead to a significantly reduced TOC.

2. Ordering and Design Process

DomeShelter™ Fabric Structures are designed and manufactured in both standard and customised sizes, with a wide range of both width and height size options available. Standard sizes are generally available “off the shelf” and can be ready to ship to site often within days of ordering. Where a fit-for-purpose solution is required, a team of dedicated in-house designers work with the client and DomeShelter™ Consultants to design and engineer custom requirements and make the process easy and trouble-free for the client.

Using Shipping Containers as a substructure for Fabric Shelters also has significant benefits and makes the process easier. The sizing of containers is standard throughout the world, contributing to a much smoother design process. The same structure can be mounted on a number of different containers, making it again much easier and time-efficient to purchase standard size Shelters.

3. Transport

All Fabric Structures are cleverly packed down into kit form onto specially designed crates and stillages for easy transport around the globe, to even some of the remotest locations. Local Australian deliveries utilise flatbed trucks and export orders are packed into a standard sea container. As a result, transport to site is cost-effective, quick and easy.

4. Installation

DomeShelter™ Fabric Structures are deliberately designed to be installed by the client’s own teams, following instructions provided. Utilising their own teams saves the client both time and money by reducing the need to introduce outside contractors to site, with the associated costs of induction and other costs of getting external contractors to site. Those clients who prefer skilled teams for installation can call on DomeShelter™ approved installers.

5. End of Project

Most projects that DomeShelter™ Shipping Container Workshops are supplied to have a pre-destined end date, ranging from a few short years to over a decade. Clearing the warehouse away is a matter of simply dismantling the structure and packing it back down into kit form for transport to the next project, storage or sale.

Site disturbance is minimal, depending on the container securing used, and so site restoration costs and effort is minimised. In many instances, the Shelter may need dismantling and shifting across site to cater to changing work conditions. It is not unusual for a Shelter to be relocated 6-8 times throughout the life of the project.

Shipping Container Workshops or Warehouses are increasingly utilised as a trusted, viable alternative to the traditional steel shed. No longer is a steel shed the first and only option considered, as the use of modern Fabric Structures mounted on sea containers presents compelling benefits.

If you need a workshop or storage solution for your project or worksite, get in touch to speak with a DomeShelter™ Consultant today.