Ammonium Nitrate is an explosive substance used in the mining industry as a blasting agent.

Being an explosive, there are strict regulations for the product, including transportation, storage and risk control. In Western Australia, it is the Department of Mines, Industry Regulation and Safety who are responsible for overseeing this. This article will refer to the Western Australian Government’s Code of Practice, but codes can be found from each State government around Australia with similar guidelines, as well as from international governments outside of Australia.

In this article, we’re going to focus on the safe storage of ammonium nitrate and how Fabric Shelters are the perfect Ammonium Nitrate Storage Solution.

Safe Ammonium Nitrate Storage Guidelines

The Western Australian Code of Practice focuses on the top three hazards associated with ammonium nitrate and the necessary safe storage control measures. The greatest of these is the explosion hazard created as a result of storing and using the highly volatile substance.

When heated by an external fire, the explosion sensitivity of the decomposing ammonium nitrate melt increases dangerously, and the sensitivity is further increased:

- If the ammonium nitrate is impure

- If it mixes with contaminants and/or fuels

- If molten ammonium nitrate becomes confined and decomposition gases cannot escape freely.

In order to guard against these hazards, there are a number of required risk control measures that must be implemented. These include:

- Removing all combustible materials and sources of ignition from the vicinity of the ammonium nitrate

- Preventing incompatible material mixing with the ammonium nitrate to preserve its purity

- Avoiding confining decomposing molten ammonium nitrate by providing adequate ventilation

- Separating stacks of ammonium nitrate to prevent a sympathetic detonation and reduce the consequences of an explosion, and separating the storage site from potential hazards

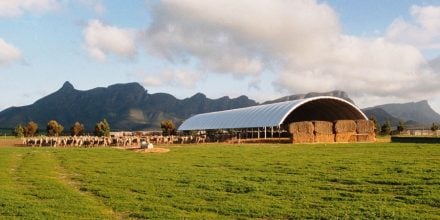

Fabric Structures for Ammonium Nitrate Storage

The guidelines all translate to ammonium nitrate storage being best suited to enclosed, lockable and well-ventilated Structures.

The WA Department of Mines’ Code of Practice specifically recommends ‘dome structures’ as they call them. These fulfil all the necessary risk control guidelines – the fabric tarp material is fully weatherproof and the Structure can be made enclosed and fully lockable to avoid cross-contamination or tampering, but parts of the structure can also be opened up to allow ventilation and airflow.

DomeShelter Australia’s Ammonium Nitrate Projects

DomeShelter Australia has supplied high-compliance DomeShelter™ Structures used for Ammonium Nitrate Storage on mine sites throughout Australia, the Middle East & Africa, and South East Asia. Project specific challenges have included:

- Design and Engineering Packages to ensure compliance and optimal design

- Painted steel framework to adhere to strict site regulations, i.e. epoxy coating with a specific colour and coating thickness

- Stainless Steel Fittings

- Armourtex® Fire-Retardant Fabric

DomeShelter™ Structures are 100% Australian-Made, manufactured using durable materials, and fully engineered to withstand up to Australian Wind Region D – Cyclonic wind speeds.

Our experienced and friendly team takes care of everything you need to buy your next Shelter, from consulting all the way through to delivery and installation, ensuring every DomeShelter™ Structure is Fit-For-Purpose and fulfils every client’s individual needs.

Examples of past Ammonium Nitrate Storage projects can be seen below.

Hanwha Emulsion Plant 500T : A fenced-off DomeShelter™ Structure mounted on corrugated iron side walls.

Rio Tinto Brockman 2 onsite AN Storage facility: A large Truss structure with curtain doors on either end.

Get In Touch

Contact DomeShelter Australia’s experienced team to learn more about how a durable, proven DomeShelter™ Structure can solve your worksite needs, or try our free 3D Design tool.