‘Mounting rails’ are mentioned a lot in conversations during the consultation and design stages of a DomeShelter™ purchase. We regard Mounting Rails as one of the most integral parts of a DomeShelter™ Structure, particularly in relation to engineering and structural capabilities. Offering a varied range of Mounting Rails is not industry standard, but the DomeShelter Team have worked to develop proven mounting systems to ensure every DomeShelter™ Structure is Engineered to Protect.

You may be confused about what exactly the purpose of a mounting rail is, and the differences between the types of mounting rails available. This short article explains the three mounting rail types we offer here at DomeShelter Australia, and why they are so important when designing a DomeShelter™ Structure.

What Are Mounting Rails?

Mounting Rails are used on DomeShelter™ Structures to connect the arched roof structure to the base or substructure it is mounted on. Common substructures include shipping containers or steel posts. The mounting rail is one of the most important elements of a DomeShelter™ Structure, ensuring the arched roof frame is correctly attached to the substructure and its weight load is evenly distributed.

At DomeShelter Australia we offer the following Mounting options:

- Welded Brackets

- Welded Mounting Rail

- Boltlock Mounting Rail

Brackets are standard for most Fabric Shelter suppliers, while the latter two Mounting Rail options have been specially designed by the DomeShelter™ Team for improved Engineering capability. While all DomeShelter™ Mounting Types are manufactured to last, some are more intensive than others and each have their own benefits to suit the individual needs of each project.

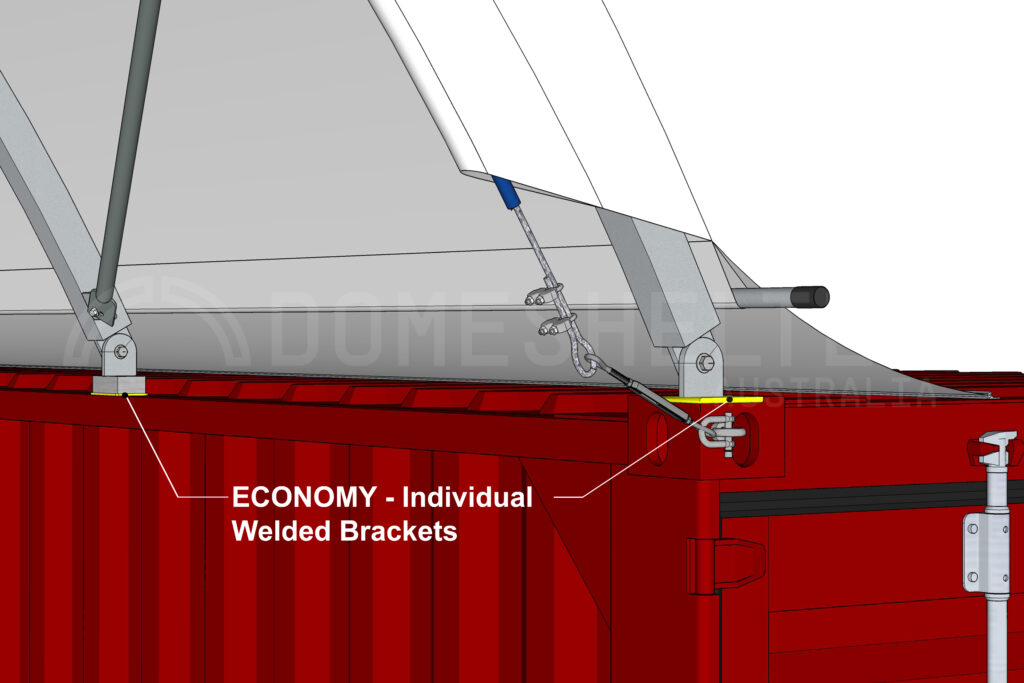

Economy Brackets

These are industry standard and the least expensive mounting option. They involve separate, individual brackets welded at intervals along the shipping container. Without a solid, load-bearing rail like that included in our other mounting solutions, the brackets are not recommended for regions with extremely rigorous conditions. They are also difficult to relocate and can be more tedious to install. Nevertheless, for small structures with tight budgets, they may be the most favourable option.

Welded Mounting Rail

Welded Mounting Rails are one solid, continuous rail, prefabricated off-site with the roof beam attachment points distributed along the rail. The rail is then welded onto the container at intervals, resulting in one solid connecting point between the substructure and the roof for improved load bearing and structural integrity.

We recommend Welded Mounting Rails as the best choice for most DomeShelter™ clients. They are generally quickest to install and cost less than Boltlock Mounting Rails, but are more intensive and structurally sound than economy Brackets. The medium cost point combined with high structural compliance means this option offers the best value for money of the three. Welded Mounting Rails can also fit any style of container.

The greatest point of difference between Welded and Boltlock Mounting Rails is their relocation capability. Welded Mounting Rails are recommended for more permanent structures. For structures that will need to be moved, Boltlock is the better choice.

Boltlock Mounting Rail

Boltlock Mounting Rails are mounting rails fabricated with attachment points that are then bolted to the substructure on-site when the structure is installed. They involve a high-level of pre-fabrication before the Shelter is sent to site, meaning there is no need for on-site welding, and installation times are dramatically decreased.

These are good for sites where it’s difficult to get welding permits. That being said, we can supply welded mounting rails to the container supplier to be pre-welded before delivery to overcome this challenge where necessary, if Welded Mounting Rails are ultimately preferred by the client.

Boltlock Mounting Rails are recommended for clients who wish to relocate their Shelter one or more times after initial installation. They are quick and easy to disassemble for better movability, as the bolts simply have to be taken out and the Shelter is then ready to be easily packed down and relocated.

They are not compatible with containers that have large horizontal flat-bars instead of SHS top rails. They also don’t work with containers that have been lined internally (for offices etc), because you can’t access the interior side of the bolt.

Which Mounting Rail Should I Use?

Ultimately, there are a number of factors that will play a part in deciding which mounting rail type is ideal for your project. Cost, compliance, wind rating, movability considerations and more should all be considered before making a conclusion.

Our DomeShelter team is always available to answer any questions about your Shelter purchase. Once all of a project’s variables are properly discussed, your DomeShelter™ Consultant will be able to make recommendations for which Mounting Rail type will be most suitable for your individual needs.

If you would like to get in touch with the DomeShelter sales team to discuss your Shelter needs, call 1300 193 188 or visit Request a Quote to submit an enquiry and one of our friendly team will be in contact.