Concrete often plays a crucial role in the installation of DomeShelter™ Fabric Structures, and is an aspect of many projects that needs proper attention and consideration. Throughout this article, we will explore the areas where concrete is most commonly used, from concrete wall-mounted Shelters to footings and hold downs and beyond.

Furthermore, we aim to clarify DomeShelter Australia’s scope when it comes to clients that require concrete. It is crucial to understand the division of responsibilities between our team and the clients to ensure a seamless project execution. We will define where our expertise starts and stops in terms of concrete arrangements, providing clarity on the process and expectations.

So, whether you are considering a concrete wall-mounted shelter, evaluating the necessity of concrete footings, or simply seeking a better understanding of DomeShelter Australia’s involvement in the concrete aspect of our structures, this article serves as your ultimate guide.

Do All Fabric Shelters Use Concrete?

When it comes to Fabric Shelters, there are specific areas where concrete is commonly used, although concrete-free projects are also possible. The decision to incorporate concrete depends on the context and variables of each DomeShelter™ kit, as they are designed to be fit-for-purpose.

The key areas where concrete is often used are:

Hold Downs

Concrete footings, external concrete ballast, etc, are often a favoured choice for securing Fabric Shelters to the ground.

Concrete Walls

For Concrete Wall Mounted DomeShelter™ Structures.

Endwall Hold Downs

Endwalls with posts/columns require concrete footings to be properly secure and achieve wind load ratings

Concrete Slabs

Where a concrete floor is desired for a Fabric Shelter.

To ensure the entire project is organised and streamlined, as well as to properly consider budgetary requirements for the entire project, all areas outside of the actual Fabric Shelter kit itself should be considered, including where concrete has to be sourced.

Concrete Walls and Hold Downs are the most common concrete variables associated with DomeShelter™ Structures, and are discussed in more detail below.

Concrete Wall Mounted DomeShelter™ Structures

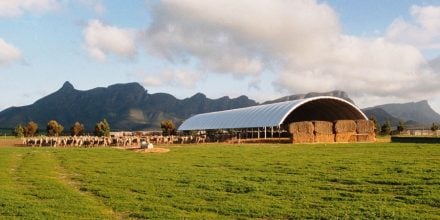

Concrete Walls are one option for a Fabric Shelter substructure, alternative to sea containers or steel posts. While concrete walls are most popular in specific industries, they are available to all clients who choose them.

Concrete walls are a popular choice for bulk storage Shelters. The strength of the concrete allows products to be loaded against the walls, optimising storage capacity and accommodating heavy loads with ease.

They are also widely used in animal husbandry due to their added strength. Concrete walls offer resistance to the destructive tendencies of livestock such as pigs.

In Defence applications, concrete walls provide additional functionality. They allow for bunding to be pressed against the Shelter sides, improving security measures.

Concrete Hold Downs

Hold downs and footings involving concrete are generally the most popular option for Fabric Shelters, especially Container Shelters.

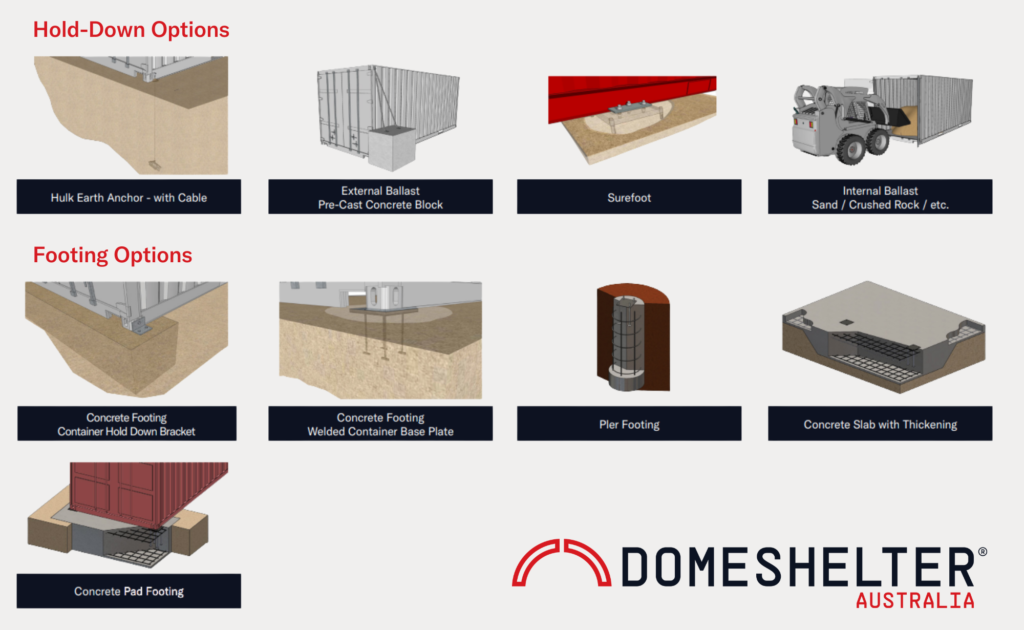

The main concrete hold downs are:

- Concrete footings in the ground

- Pre-cast concrete blocks chained to the Shelter

- Concrete slabs

There are concrete-free options, such as ballast inside sea containers (this can be crushed rock, sand, or any other heavy material), or concrete-less footing alternatives such as Surefoot.

The hold down options for any given Fabric Shelter will depend on the size of the Shelter and the wind load requirement for your area. These variables will typically point to a recommended hold down option to ensure the safety and durability of your specific Shelter, as there is no one-size-fits-all answer.

Does DomeShelter Australia Organise My Concrete?

DomeShelter Australia’s expertise and area of focus is in the supply of high-quality, fully engineered Fabric Shelter kits. While we emphasise comprehensive projects, there are elements of DomeShelter™ projects that we encourage clients to outsource from suppliers who specialise in those areas.

Our engineering team can design footings and provide information to simplify the procurement process, integrating this into your project scope. However, arranging and providing concrete remains the responsibility of the customer.

With over 25 years of experience and an in-house design and engineering team, DomeShelter Australia can provide valuable information to be passed on to concrete suppliers. Our team is available to discuss recommendations, ensuring a cost-effective and efficient process. We emphasise the importance of considering the total project scope and long-term outcomes to save clients time and money.

Case Study: Abra Mining

To illustrate the value of considering the entire project scope, let’s examine Abra Mining’s Core Sample Shelter. Initially, a Post Mounted design with standard hoops and 2-metre post spacing resulted in significant footing requirements.

With this in mind, the team designed an alternative Shelter that incorporated truss members, reducing the number of posts and optimising the use of concrete for the Shelter’s footings. Although the Truss Shelter may have seemed more expensive initially when looking only at the cost of the Shelter Kit, a comprehensive analysis of the entire project scope revealed substantial savings, as far less concrete was required.

Conclusion

In conclusion, concrete often plays a crucial role in DomeShelter™ Fabric Structures. Whether you are considering a Concrete Wall Mounted Shelter, evaluating the necessity of concrete footings, or seeking a better understanding of DomeShelter Australia’s involvement in concrete procurement, this article serves as your ultimate guide. By considering all variables, making informed decisions, and understanding DomeShelter Australia’s scope, you can enhance the strength, durability, and efficiency of your Fabric Shelter projects.

Read more about DomeShelter™ Structures by visiting our learning centre, or get in touch directly with the team today.