‘Fabric Structure’ is an umbrella label encompassing Structures of a range of designs and configurations, that use Fabric as the main roof element.

Fabric Shelters can be mounted on different substructures – containers, posts, concrete walls, etc. The frames themselves can also change depending on project requirements – the two main options for DomeShelter™ Structure frames are ‘Single Hoop’ and ‘Truss’.

Truss Structures are sometimes viewed with apprehension, as they may appear to have a higher upfront cost, leading clients to question a Truss Shelter over a single hoop option. However, Truss Shelters offer structural efficiencies that are much better suited to certain project parameters.

This article clarifies the differences between Truss and Single Hoop Shelters and explains why a Truss Shelter may be recommended for certain projects.

What is a Truss Structure?

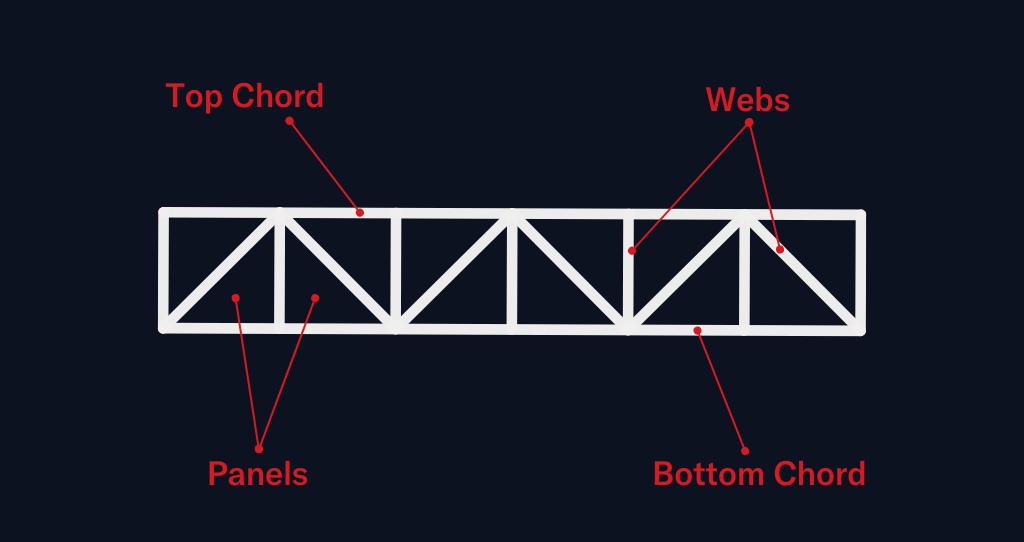

A ‘Truss’ is a framework of interconnected, strategically arranged parts – straight or curved – shaped into triangles for maximum strength. Within this setup, you’ve got:

- Top beams (top chords),

- Bottom beams (bottom chords)

- The supporting beams in between (webs)

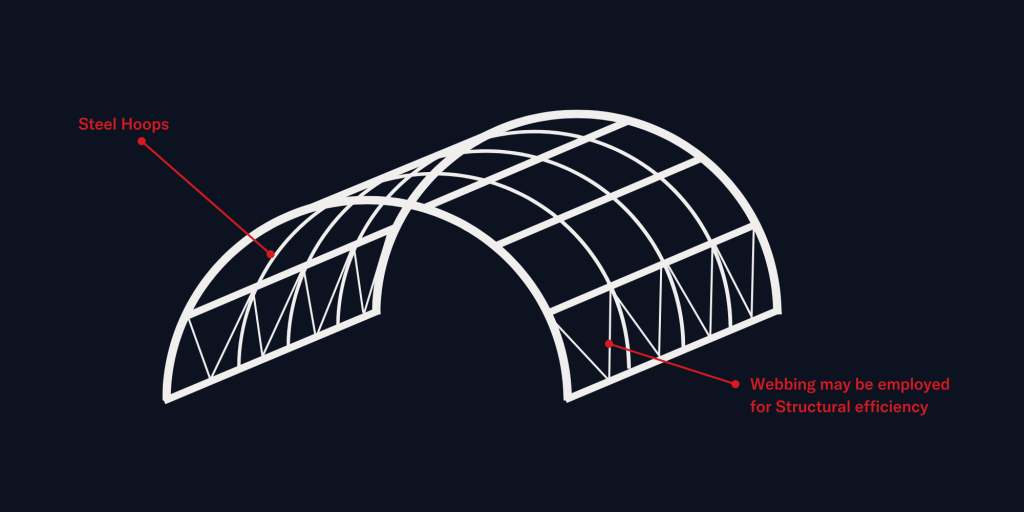

When it comes to DomeShelter™ Structures, these trusses lock together to form a durable framework for the Shelter. Once this frame is in place, the tarp is tensioned over it, forming the Shelter.

Single Hoops, seen on smaller DomeShelter™ Structures, involve individual solid curved beams that are then interconnected to form the Structure.

What are the Benefits of Truss Structures?

Truss Structures offer key benefits in a few main project areas, especially in terms of strengnth, structural efficiency, and ease of installation, especially as Shelters get larger.

Strength and Durability

In almost all industries – mining, industrial, defence, etc. – strength is non-negotiable. This is where Truss excels, with unprecedented durability and load-bearing capacity. Truss efficiently distributes weight and stress, ensuring resilience against adverse weather and challenging operational environments.

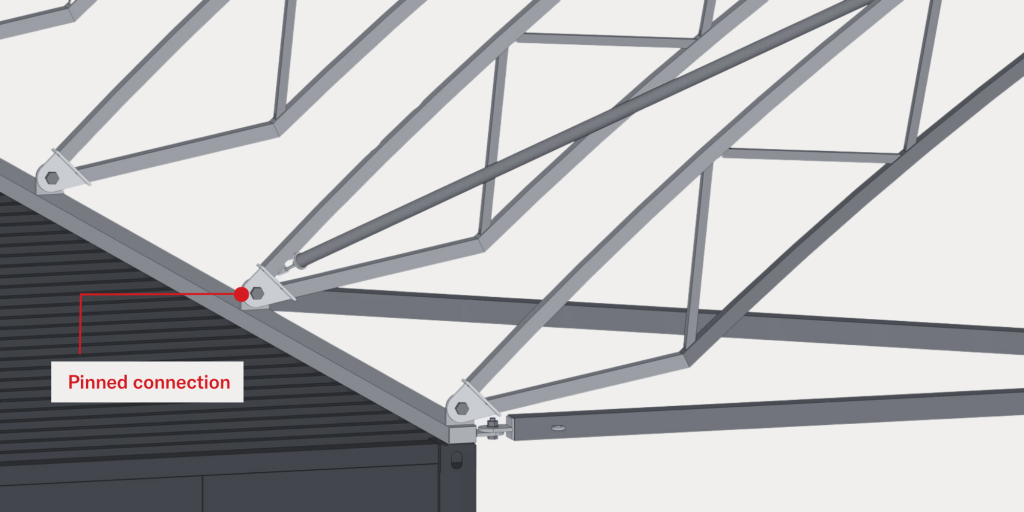

Furthermore, when it comes to structural integrity, pin connections play a pivotal role. Unlike fixed connections, which might strain under extreme wind forces, pin connections enable Truss elements to move slightly, better dissipating and distributing wind loads. Studies and engineering analyses have shown that Truss Structures with pin connections can exhibit significant improvements, sometimes in the range of 10% to 20%, in their ability to handle wind loads. These percentages can fluctuate based on the specific design considerations and the magnitude of wind forces acting on the structure.

Fast Installation

Time is money in many industries, and every second counts. Truss Structures, especially when dealing with large profiles, facilitate rapid installation with fewer pieces and less ‘bits-i-ness’. This helps to reduce downtime and expedite project timelines.

Structural Efficiency

In more complicated engineers terms, at the heart of the discussion about Truss Structures is the question of ‘structural efficiency’.

Trusses are more suitable over long spans than solid beams, due to the direction and type of force that they contain.

There is a transition point – dictated mostly by span length, and accompanied by loading, where trusses become more efficient than single hoop solutions. This can vary depending on wind regions, but generally where spans start exceeding 20m, trusses become more economical.

Are Truss Structures More Expensive?

The short answer is: it depends. This can be a frustrating answer, but the difference between single hoop and truss can’t be looked at based on just face value price, as the factors involved are varied and complex.

When it comes to design elements relating to Shelters, it is important to ‘compare apples to apples’; in the case of DomeShelter Australia, our experienced consultants are committed to providing lifelong value to clients, and would only recommend a Truss solution where it would be more economical overall.

A standout feature of Truss frames is that they can achieve what is called ‘portal action’. This means that footings can be pinned to the frame; on the other hand, a single hoop Shelter doesn’t facilitate portal action, so it needs fixed base foundations. What this means is that, for large Structures, a Truss design will typically make more sense cost-wise in terms of overall project cost, because they usually require less concrete for foundations compared to a single hoop design.

Is Truss Better Than Single Hoop?

It’s essential to understand that Truss Structures and Single Hoop Structures both serve distinct purposes in Fabric Shelter design.

Both types are designed with structural integrity; structural efficiency is a more accurate term to describe the differences between Truss and Single Hoop. Designing a load bearing structural system is all about balancing the structural system to meet the load demands.

As mentioned above, Truss designs become the more suitable option for overall project cost-efficiency around where spans start exceeding 20m. In these cases, Truss will more often meet serviceability requirements and functional performance criteria to ensure a compliant, effective Structure that is properly engineered.

In contrast, Single Hoop Structures are generally more suitable for applications with smaller spans.

The choice between the two depends on the specific project requirements, such as span lengths, loading conditions, and budget constraints.

Get In Touch

DomeShelter Australia’s experienced team is here to help; if you have any further questions about the benefits of a Truss Fabric Shelter, visit our contact page and get in touch with the team today.

For more information about Fabric Shelters, visit our comprehensive Learning Centre for free articles, case studies, videos and more.