DomeShelter Australia has played a pivotal role in addressing the unique challenges faced by industries in Africa, particularly in the mining sector. With a dedicated International Projects Team, DomeShelter Australia has been actively involved in numerous large-scale projects throughout the continent, delivering innovative Shelter Solutions that surpass expectations.

Challenges in African Industries

Industries in Africa face a range of challenges that have the potential to significantly impact operational efficiency and success. Infrastructure limitations and high construction costs can lead to inadequate on-site facilities. Harsh weather conditions, including extreme heat and heavy rainfall, further compound these challenges. Additionally, industries such as mining are often located in remote and challenging terrains, where access is difficult and surrounding resources are sparse.

DomeShelter™ Structures have been trusted by leading companies, especially in the African mining industry, for decades. With significant experience in the Australian mining sector, DomeShelter Australia is no stranger to harsh weather and remoteness, able to work with clients through these challenges with ease. All DomeShelter™ Structures are fully engineered and manufactured to strict international standards. Their unique modular design and efficient kit packaging makes them well suited to industries throughout Africa; Kits can be shipped inside ISO sea containers for easy delivery to even the most remote locations, providing quality Shelter Solutions that remain cost-effective and hassle-free for the client.

DomeShelter™ in Africa

With a dedicated International Projects Team, DomeShelter Australia has been involved in a number of large projects throughout Africa.

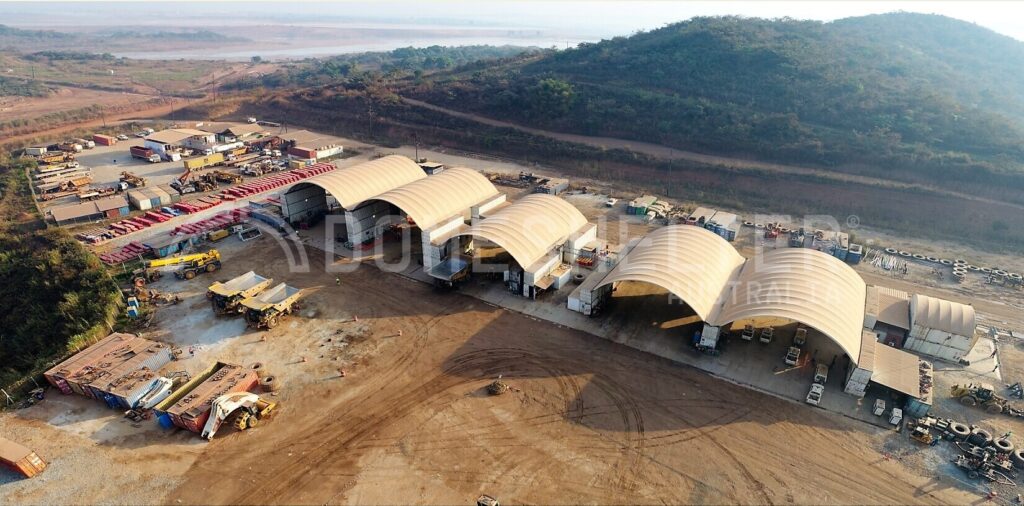

When Shelter was required at the sprawling Kibali Gold Mine in DRC, to ensure activities related to vehicle maintenance could be completed efficiently and staff and assets could be protected from harsh elements, DomeShelter Australia were approached to assist.

Located at a remote site, they needed a solution that could be easily transported and installed without comprising on size and durability. They also needed it to be delivered in a short time frame while remaining on budget.

Six DomeShelter™ Structures of varying sizes were provided for use on site. They serve a range of purposes, from Maintenance Workshops and Lubrication Bays to Boilermaker Workshops and Tyre Bays. Mounted on double and triple-stacked sea containers, the Shelters offer ample height clearance for large mining machinery such as CAT dump trucks to be worked on undercover. The Shelters were able to be installed by local teams on-site following comprehensive instructions provided, saving time and cost for the client.

An older project involved supplying a Heavy Vehicle Maintenance facility to the Yanfolila Gold Mine in Mali. Two interconnected 15m wide x 18.3m long Shelters make up the huge facility on site. In the seven years since the Shelters were installed they have protected countless staff and assets from the harsh Sahara conditions.

Panafrican Equipment Group has worked with DomeShelter Australia on a number of its African mining projects, such as at the Tarkwa Gold Mine in Ghana. The DomeShelter™ Team designed and manufactured a fit-for-purpose Heavy Vehicle Maintenance Bay to support operations at the mine. The project scope included full facility delivery, consisting of two 21m wide by 18.3m long hot dip galvanised Truss Super-Rise Fabric Shelters mounted on double stacked GP Sea Containers.

Other high-profile projects in Africa have included:

- Barloworld Equipment 12m wide x 12.2m long x4

- Iamgold 14m wide x 61m long

- Basil Read Mining 21m wide Super Rise x 27.4m long

DomeShelter™ Africa Customer Testimonials

One of DomeShelter Australia’s largest projects in Africa to date is at Centamin’s Sukari Gold Mine in Egypt, where over a dozen DomeShelter™ Structures have been installed since the mine began production in 2009.

The Sukari mine is located in a remote, isolated desert region, where the landscape and climate are unforgiving. Protection for Centamin’s people and assets from the harmful effects of the elements was vital to uphold their dedication to a safe and healthy work environment.

On Centamin’s end, many of these installations were managed by contractor Eric, who gave a very positive testimonial about his experience working with DomeShelter Australia.

“Great product, super easy to install with high quality. Would recommend DSA to anyone,” he wrote on social media. “I always pushed to get [DomeShelter™ Structures] as the cost was always lower than building a structural steel building of equivalent size and labor for installation there was no comparison. Overall a very quick, cost effective and labor efficient product.”

Another Project Manager from the Sukari Mine also added his own experience, praising the “very fast construction” of DomeShelter™ Structures, saying they were tested and proved themselves “under really tough conditions, sun, wind and heavy rain”.

Benefits of DomeShelter™ for Clients in Africa

DomeShelter™ Structures are the modern alternative to traditional building types, responding to the demands of modern industries with trustworthy, durable infrastructure solutions.

With quick-turnaround Standard Solutions available for rapid dispatch, as well as an experienced in-house team able to deliver even the most complex Fit-For-Purpose project scopes, DomeShelter Australia offers a range of unique benefits for international clients.

Speed and Ease of Install

DomeShelter™ Kits for overseas project delivery are typically packaged inside ISO sea containers. This offers a range of benefits, including:

- Standardised ISO sizing means straightforward delivery to any location internationally

- Easily liftable for unloading

- Easy to unpack on-site

- Packaged safely for delivery and movement

- Space saving; multiple DomeShelter™ Kits can be packed inside one container depending on size

Fewer overall pieces than other products on the market means that DomeShelter™ Structures have improved Structural Strength and significantly reduced installation times and costs once the Shelter reaches site. Two 15m wide by 12.2m long DomeShelter™ Structures on a remote mine site would take an estimated 3 days to install, compared to more than a week with a complicated & ‘bitsy’ alternative option.

Quality and Durability

DomeShelter Australia is the original manufacturer of genuine DomeShelter™ Products, with 30 years of industry experience in designing and manufacturing fully-engineered Shelter Solutions.

Fully in-house design, engineering, and manufacturing ensures that every DomeShelter™ Structure adheres to strict quality control standards and is 100% Australian made using only the highest quality materials.

Conclusion

DomeShelter™ Structures have become integral to the success stories of various industries in Africa, offering not just shelter but adaptable, durable, and innovative solutions tailored to the unique challenges faced by clients across the continent.

Visit our contact page to get in touch with our experienced International Projects team and solve your infrastructure needs. For more information about our DomeShelter™ Products, case studies, videos and more, visit our comprehensive Learning Centre.