Planning ahead and being prepared are vital for risk mitigation – this includes considering the potential outcomes of even unlikely events, such as lightning strikes or earthquakes.

Particularly for clients who are located on or near fault lines, analysing how a structure will perform in a seismic event is a vital component of the selection process when choosing an appropriate Structure for their region.

Customers will sometimes ask how Fabric Structures perform in earthquakes. This article explains what makes a Fabric Structure well-suited to withstanding seismic waves.

What is the Best Structure for Withstanding Earthquakes?

Ductile buildings are safest in seismic events as they dissipate energy from seismic waves. Ductility describes the extent to which a material or structure can undergo large deformations without failing. The term is used in earthquake engineering to designate how well a building will endure large lateral displacements imposed by ground shaking.

A structure that is too stiff or brittle will be prone to failure under relatively small deformation demands. A ductile structure’s ability to contort and dissipate energy during an earthquake is, therefore, advantageous as the structure will keep deforming without reaching ultimate failure or collapse.

A brittle structure such as a masonry building will tolerate very little displacement before the onset of damage. These buildings are all but guaranteed to fail in a significant seismic event.

Fabric Structures: The Ideal Ductile Structure

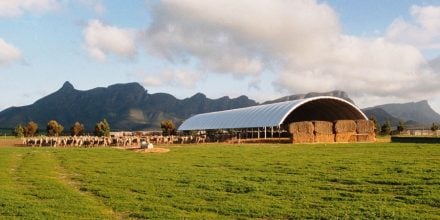

Fabric Structures are classified as lightweight, ductile structures, and thus are not structurally affected by light ground movement. The steel frame that forms a Fabric Structure gives them a degree of elasticity that enables them to undergo deformations before the onset of failure.

Other, more traditional structures, such as concrete, can be optimised for seismic events using techniques such as braced frames and reinforced joints, but Fabric Structures are pre-qualified for earthquake resistance without requiring further intervention.

Fabric Shelters can also have advantages in other extreme weather events and disasters, with lightning protection kits and fire-rated tarp fabric available. DomeShelter™ Structures are fully engineered by an experienced in-house team, and can withstand winds up to Australian Wind Region D – Cyclonic speeds.

DomeShelter Australia: Australia’s Leading Fabric Shelter Manufacturer

DomeShelter Australia has been designing and manufacturing 100% Australian Made Fabric Structures for over 25 years. We export direct from our purpose-built facility in regional Western Australia anywhere in the world, including some of the most remote and rugged global locations.

DomeShelter™ Structures are Fit-For-Purpose to suit every individual project, with customisation options including different substructures, endwalls, flooring, lighting and more available on request.

Safety is an important pillar of our business, and every DomeShelter™ Structure is manufactured from durable steel and tear-proof Armourtex® Tarp to withstand even the harshest conditions and protect our customers’ people and assets.

If you would like to explore potential Fabric Shelter configurations to see if they can fulfill your company’s needs, visit our free, easy to use 3D Design tool, available any time on our website. You can also contact our team directly if you have any questions or want to enquire about a genuine, earthquake-resistant DomeShelter™ Fabric Structure.