If you’re a Project Manager or in a similar position, you may be wondering how you can minimise your environmental footprint while still incorporating all the necessary infrastructure to keep the site running smoothly.

Words like ‘rehabilitation’ and ‘remediation’ are becoming increasingly important on mine sites around the country (and the world). Having a strategy for site rehabilitation from the outset is now a necessity for Project Managers, due to updated mining regulations.

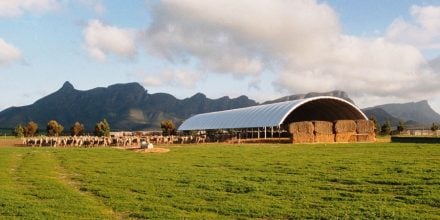

Fabric Shelters are a durable, modular solution that allows Fit-For-Purpose infrastructure while still making site remediation easy.

Mine Site Rehabilitation Requirements

The Australian government requires that rehabilitation be a key aspect of any new mine proposal. The Mine Rehabilitation Leading Practice Sustainable Development Program, published in 2016 by the Australian Government’s Department of Industry, outlines the requirement for leading practice rehabilitation to start at the beginning of the project.

Failure to prove a strong commitment to environmentally conscious land-use, particularly to successful site remediation, can lead to approval delays and, in the worst case, proposals being rejected.

Mine site rehabilitation needs to meet three key objectives:

- The long-term sustainability of the site’s landforms, soil, and waterways

- The partial or full repair of the site’s ecosystem and its ability to provide habitats for fauna and (if applicable) services for people

- The prevention of pollution of the surrounding environment.

As the Handbook outlines, failure to plan and start rehabilitation and footprint minimisation strategies may make it difficult to deliver a sustainable outcome that meets the required success criteria.

Identifying potential threats – and opportunities to reduce unnecessary disturbances – early on is one of the easiest ways to make sure mining operations don’t reduce their available rehabilitation options by the time of the mine’s closure.

The handbook makes clear how vital a consideration of mine site rehabilitation is: “To ensure continued access, Australian mining companies must demonstrate their commitment to sustainable development to regulators.”

Fabric Shelters for Easy Mine Rehabilitation

Fabric Shelters are the modern alternative to traditional structures, such as steel sheds. Steel structures are typically complicated to construct and permanent, leaving a significant footprint even when removal is attempted.

Fabric Structures are transported in kit form and easily installed without the need for outsourced contractors, overall resulting in a significantly reduced lead time compared to more traditional structure types.

Their unique modular design means that Fabric Shelters can be disassembled and moved around or off-site, with little to no disruption to the site where it was installed. Container Mounted Shelters can be installed with hold-down systems, meaning no disturbance to the ground around the Structure needs to take place. In the event they are packed down and moved, they leave almost no sign behind – this helps make successful mine site rehabilitation dramatically easier to achieve.

DomeShelter Australia

With over 25 years’ experience constructing durable Fabric Shelters, DomeShelter Australia is the industry’s leading manufacturer. Trusted by some of the largest mining companies within Australia and internationally, every DomeShelter™ Structure is designed and engineered to be fully Fit-For-Purpose and manufactured in-house at our state-of-the-art facility in regional Western Australia.

If you would like to learn how a reliable, Australian-Made DomeShelter™ Structure could work on your mine site, try our free 3D Designer, or get in touch with a member of our friendly team today.