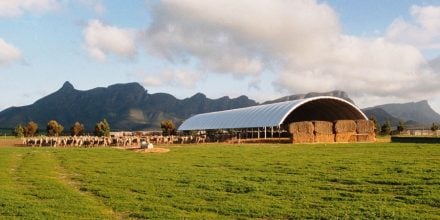

In the ever-evolving landscape of industries such as agriculture, mining, construction, and logistics, the need for reliable Shelter Solutions has never been more critical. Whether it’s protecting valuable assets, equipment, or people from the elements, a well-chosen Shelter can make a significant difference in maintaining productivity, safety, and overall operational efficiency.

As with any product, there is a variety of price points for all Shelter options on the market. When it comes to Fabric Shelters, these cost varieties can be extremely dramatic. The allure of low-budget options can sometimes lead to poor Shelter choices that result in hidden costs down the line, if not worse.

The Temptation of Low-Cost Fabric Shelters

When it comes to most investments, low-cost options can be hard to resist. The promise of saving money upfront can be appealing, especially in industries where budgets are closely monitored. But the saying goes, “you get what you pay for,” and this holds especially true in the realm of infrastructure/shelter choices.

Many imported Fabric Shelters are at a much lower price point than products manufactured in Australia, which can lead to confusion among customers. However, these shelters are not manufactured to the same standards as those made in Australia, and opting for the lower-cost imported variety can have serious implications for customers.

Short-Term Savings, Long-Term Consequences

Opting for a cheap Fabric Shelter may seem like a cost-effective solution initially, but the hidden costs can quickly add up. These costs often emerge over time, and they can have a profound impact on both your bottom line and overall efficiency of operations.

Inadequate Protection from the Elements

One of the most significant drawbacks of poor Fabric Shelter choices is inadequate protection from the elements. Low-cost shelters may lack the durability and structural integrity needed to withstand harsh weather conditions.

They may also be manufactured using inferior materials that are unable to properly protect from rain, wind, and other events. For example, a cheaply manufactured Fabric Tarp may allow water to leak through, or lack sufficient UV treatments to properly protect from the sun’s rays.

As a result, assets, equipment, and people within these shelters can be exposed to moisture, wind, and extreme temperatures, leading to premature deterioration, corrosion, damage, and safety hazards.

Frequent Repairs and Replacements

Cheap Fabric Shelters are often built with substandard materials and construction techniques. This can lead to a cycle of frequent repairs and replacements as these shelters struggle to hold up against the wear and tear of daily use and adverse weather conditions.

These Shelters often lack sufficient warranties, meaning any damage repairs will put the customer out-of-pocket. The costs associated with constant repairs and replacements can quickly outweigh the initial savings of choosing a budget-friendly shelter.

Impact on Operational Efficiency

The negative impact of poor Fabric Shelter choices extends beyond the physical condition of assets and equipment. Downtime due to repairs and replacements can disrupt operations, leading to lost productivity and missed deadlines.

Safety Hazards

Safety is paramount in any industry, and choosing a subpar Fabric Shelters can create unforeseen safety hazards. Shelters that lack proper engineering and construction may pose risks to workers and assets. Collapses or structural failures can result in injuries and even fatalities, leading to potential legal liabilities and reputational damage.

The Long-Term Value of Quality

While a low-cost Fabric Shelter option may be tempting, the hidden costs associated with poor Shelter choices paint a different picture. Investing in quality shelters from the outset can yield substantial long-term value.

Suppliers including DomeShelter Australia, who have decades of experience in designing, engineering and manufacturing using only the highest-quality materials; although at a higher initial price point, provide a long-term offer of quality and a solution clients can trust.

The True Cost of Quality

By investing in shelters that are specifically designed to withstand the rigors of the elements and intended usage, clients avoid the hidden costs associated with repairs, replacements, and operational disruptions.

Customised Solutions for Lasting Results

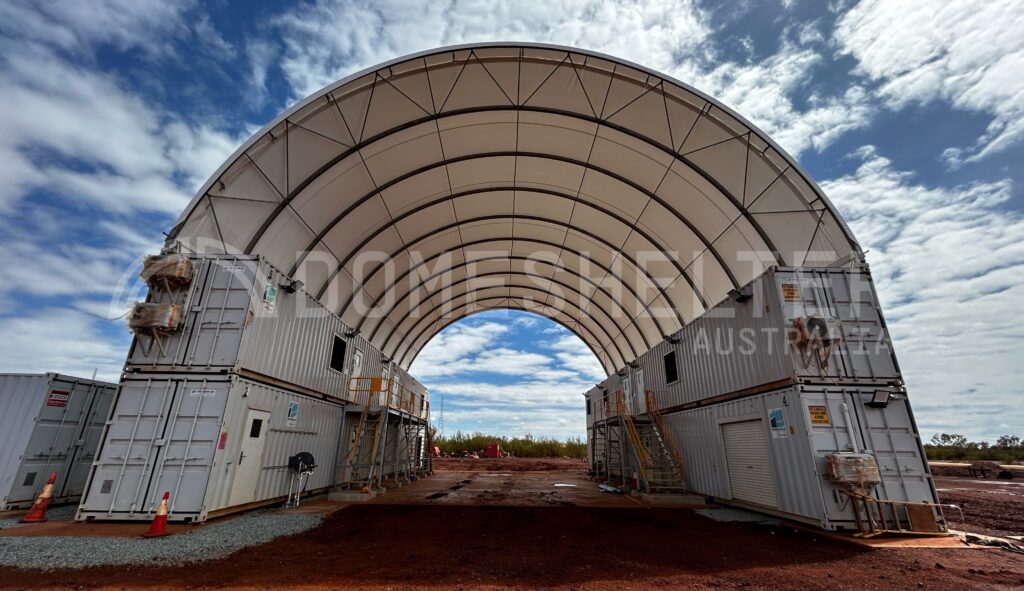

As opposed to a limited range of off-the-shelf, imported options, higher-quality suppliers such as DomeShelter Australia have in-house design and engineering capabilities that allow for customised solutions to meet the needs of each individual client.

A solution that is fit-for-purpose ultimately yields better long-term value, as it suits the intended purpose with customisations that improve efficiency and optimise workflows.

Making a Wise Investment

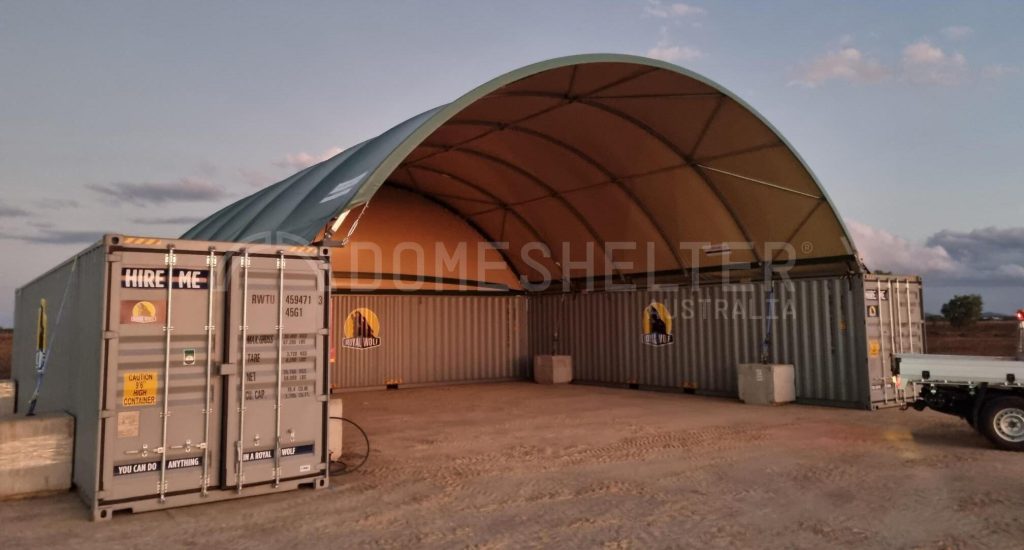

DomeShelter Australia understands the pitfalls of poor Fabric Shelter choices and focuses on providing reliable, durable, fully-engineered Shelter Solutions.

Backed by over 25 years of experience, when you purchase a DomeShelter™ Structure, you are purchasing a promise of quality, decades of experience in some of the harshest conditions on Earth, and ultimately a product you can trust to stand the test of time.

Conclusion: Making Informed Choices

When it comes to Fabric Shelter choices, it’s essential to look beyond the initial cost and consider the hidden expenses that can arise from a lower-quality investment. Opting for a low-cost Shelter may seem like a way to save money, but the long-term consequences can be substantial. What may save in capital cost upfront could well cause much greater losses later down the track, in inefficiencies, damaged products, injury to staff or worse.

Investing in reputable Fabric Shelter Solutions, such as those provided by DomeShelter Australia, ensures a product that will stand the test of time and continue to provide long-term value, allowing for sustained productivity, safety, and operational success.

If you’re interested in how a fully engineered, fit-for-purpose DomeShelter™ Structure could improve operations on your worksite, get in touch with the team today, or try our free 3D Design Tool to see for yourself.