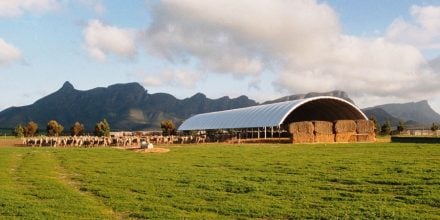

‘End Walls’ are a common feature added to many Fabric Shelters. Typically constructed from the same Polyethylene fabric as the roof, they are used to enclose one or both ends of the structure or provide partial enclosure as an added measure against the elements.

They are suitable for situations where added privacy or greater protection from harsh elements (especially wind) are desired. There are a number of different End Wall types, sizes, materials and customisations to choose from, and cost can vary heavily depending on these factors.

DomeShelter Australia has been providing quality Fabric Shelter solutions to a range of industries in Australia and around the world for over 25 years. This article details what End Walls are, different End Wall possibilities, and why some may be more costly than others.

Endwall types

There are five standardised End Wall configurations generally added to Fabric Structures. They are as listed below:

Full Endwall

A solid fabric wall with supporting steel posts that encloses the entire structure, on one end or both. This offers substantial protection from strong winds, dust, rain and UV rays, as well as security and greater privacy.

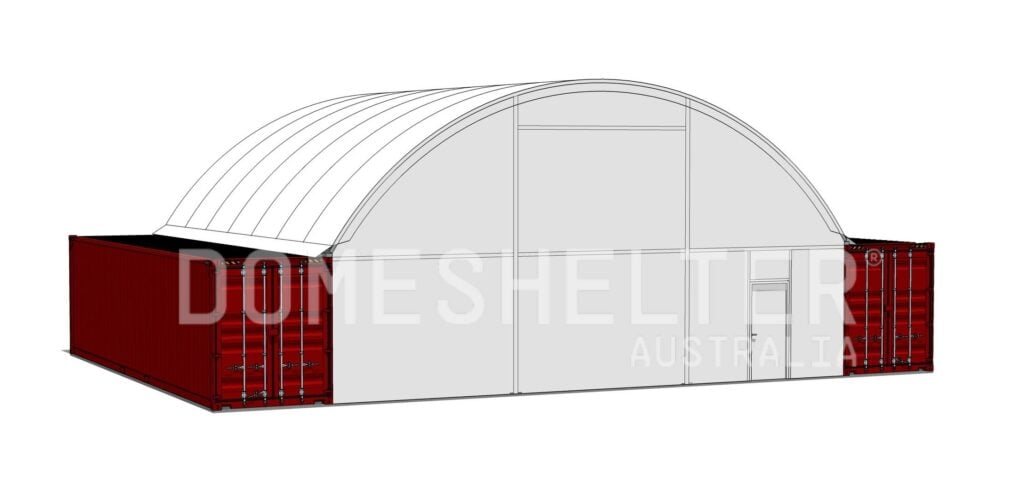

Suspended Partial Endwall

Covering just the arch, partial End Walls can help provide extra protection against dust, UV rays and heavy rain while still allowing relatively unrestricted access. Depending on the size of the Structure, more rigorous engineering requirements can lead to suspended End Walls being a more expensive option.

Column Supported Partial Endwall

Partial End Wall covering the top of the arch with columns for additional structural support. Load bearing column supports are generally required for larger Structures as specified by engineering requirements to ensure the stability of the Structure.

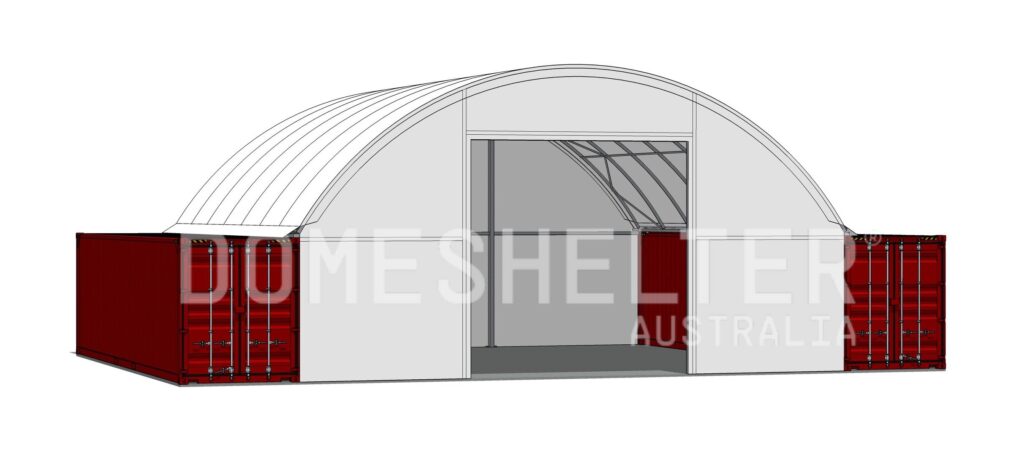

Container Supported Full Endwall

A partial end wall covering the top arch, mounted onto a third shipping container, to form a full End Wall enclosing the entire end of the structure.

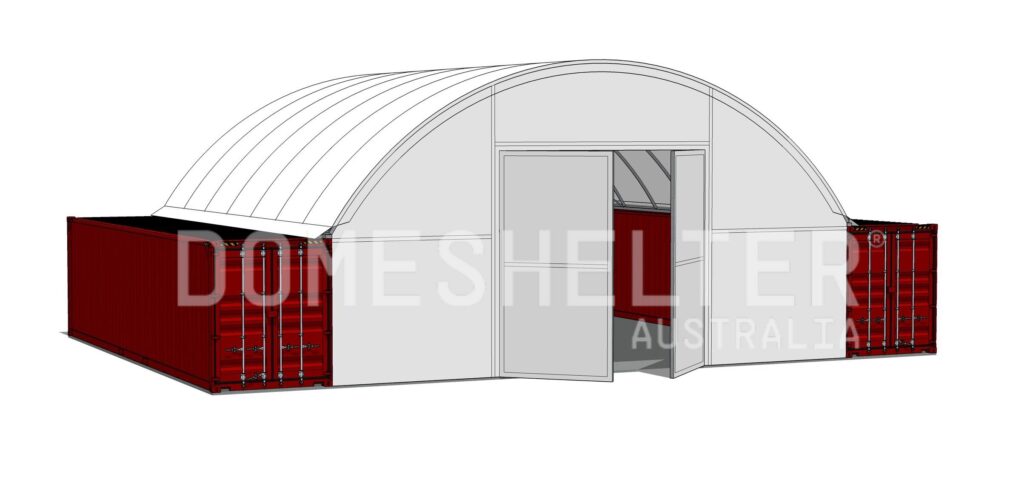

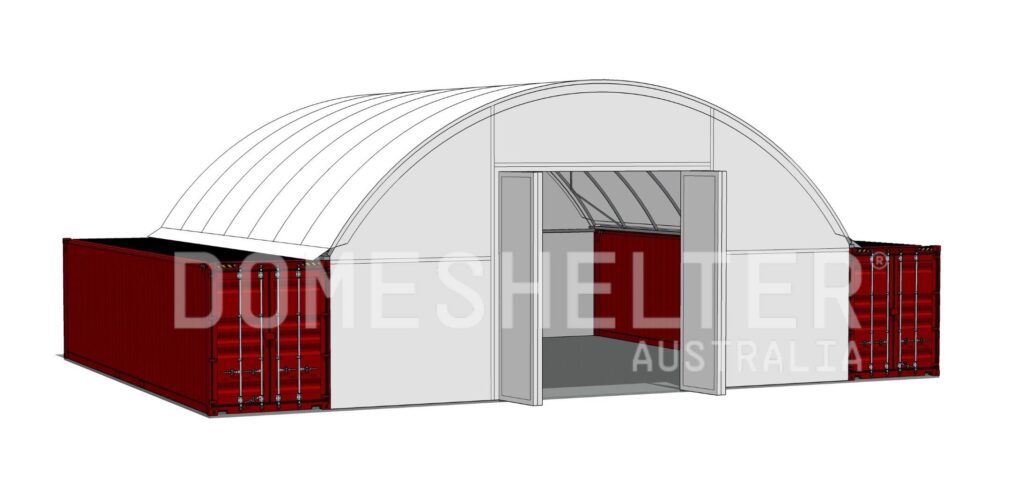

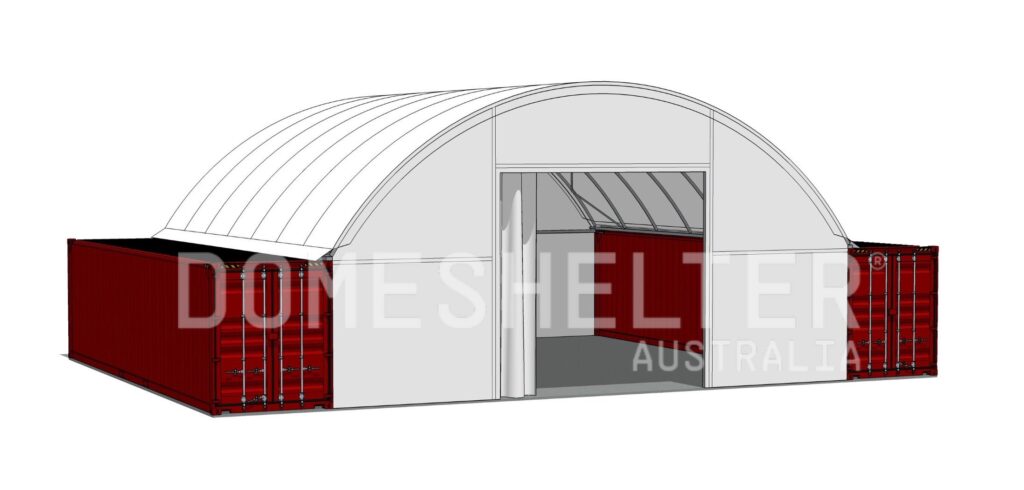

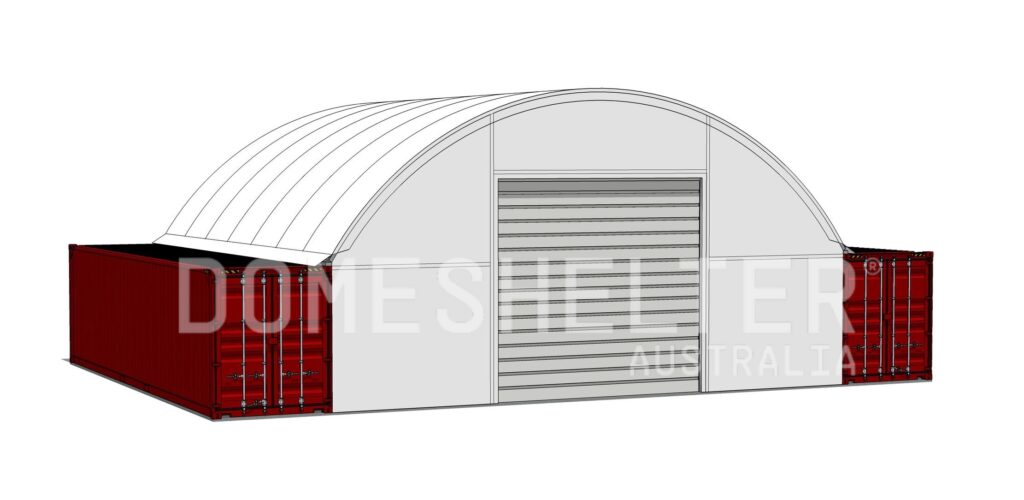

Doorway Opening Endwall

A full End Wall with a cutout for doorway access.

EndWall Customisations

It is difficult to give a definitive answer to the question of End Wall cost, as End Walls are rarely standardised and depend heavily on the Fabric Structure’s configuration and what specific requirements the individual customer needs.

End Walls can be customised for specific shipping container configurations. The engineering specifications of an End Wall may also have to be altered according to the wind region the structure is located in.

DomeShelter Australia offers a variety of End Wall customisation options to ensure each End Wall is sufficiently fit-for-purpose. Customisations and accessories available will vary depending on supplier.

Endwall Material

End Walls are most commonly constructed from the same white Armourtex fabric used on the main roof structure

Other materials are available to suit alternative customer needs. Most can be arranged on request, but examples of alternative materials include:

- Fire retardant fabric

- Green or silver colour fabric

- Full or partial metal cladding

Louvres and Wind Vents

Louvres or vents can be added to an End Wall to improve airflow within the Structure. They also reduce excessive pressure build-up within the structure in strong wind events, helping with structural integrity.

Doors

There are a range of door options available to suit various access requirements.

Pre-Hung Personnel Access Doors

Hinged Double Doors

A simple swinging door arrangement where two door panels are hinged and swing outwards. Limited to 7m wide by 6m high. Careful operation is required for larger doors.

Bi-Fold Doors

Similar to the hinged door, but with improved safety and handleability, as there’s less wind catchment. Maximum width of 10m. Careful operation required for larger doors.

Curtain Doors

Economy option, recommended for short term or low use requirements. Suitable for up to 8m wide and 4m high.

Roller Shutter Doors

Light industrial door solution which is quite popular due to being an effective, simple to install and well-fitted solution, for doorways up to 6m high by 6m wide. Heavy-duty industrial roller doors can be fitted for larger openings up to 8m high by 9m wide. The maximum height or width of these doors may also be determined by the design’s wind rating. Roller doors are among the more expensive door options.

Sliding Doors

Panels roll across the door opening on a bottom track; the door panel quantity depends on the size of the opening and how much clearance there is beside the doorway to house the panel(s) when open. Suitable for large, clear span openings.

EndWall Price Points

With such a varied range of types, sizes and customisations available, cost estimation is not a straightforward process. Different materials, metal frames required for structural integrity, wind classification, door systems and other factors all have the ability to drive End Wall costs up.

Wind Regions can lead to variability in End Wall pricing. An End Wall engineered and manufactured to withstand cyclonic winds will inevitably come at a greater cost than an End Wall located in an Australian Wind Region A area. Extreme heights can lead to structural alterations that will influence pricing. Hold down requirements (footings or otherwise) also influence costs.

Costs may further vary based on supplier. DomeShelter Australia strives to offer the highest quality Fabric Shelter Solutions, with premium materials and intelligent engineering and manufacturing processes to ensure every product is built to withstand the elements and pass the test of time. A full 12x12m DomeShelter Australia End Wall, with no doors or other added extras, would start at around $9K. DomeShelter Australia offers fully framed End Walls, whereas other companies often don’t, leading to a potentially greater price point.

Cost Examples

As a general rule, DomeShelter Australia’s End Wall pricing is not dissimilar to the price rate per square metre for the Shelters themselves, as both are constructed using similar materials with steel framework and tarp covers.

As an example, a small suspended partial End Wall – say, a 12×12 Structure in Wind Region A – would be the cheapest End Wall variation, starting at around $5K. On larger structures where more engineering and steel work is required to bear the load, however, suspended End Walls are more expensive.

In comparison, a partial End Wall with column supports for a 12x12m Structure starts at around 6K, but becomes a more cost-effective option for larger shelters as columns offer the necessary structural integrity.

DomeShelter Australia Endwalls

DomeShelter Australia provides engineered solutions for the client, designed to fit the Shelter configuration that works best for them. Other suppliers may not offer fully customised solutions or include engineering for End Walls, which can result in a poorly fitted and designed product once it gets on site. Loose fitted End Walls can result in premature wear and ultimately failure, so it’s important to work with a company that prioritises attention to detail. When browsing End Walls, it is important to measure cost discrepancies against the importance of fulfilling project requirements with an effective and safe product that is designed to last.

DomeShelter Australia uses high-grade steel sections and manufactures in Australia for Australian conditions, and our Structures and End Walls are Engineered to Protect™. This level of care and attention to detail comes with a higher price point, though we work hard to ensure our products are as cost-effective as possible. If you would like to enquire about our End Wall systems, contact our friendly customer service team at 1300 193 188 or submit your enquiry via Request a Quote.