Weather hazards can pose significant risks to valuable equipment in various industries. Rain, extreme temperatures, hail, and other weather events can cause damage, reduce performance, and lead to costly repairs or replacements.

Because of this, safeguarding equipment from adverse weather conditions is crucial to ensure the longevity and reliability of assets, minimise downtime, and maintain operational efficiency.

Shelters play a critical role in protecting valuable equipment from the harmful effects of the elements. They offer a secure and weather-resistant environment, shielding equipment from rain, wind, sun, and other events.

This article will delve into the common weather hazards that pose risks to equipment, exploring the potential damages and challenges they present. We will then discuss how Fabric Shelters are a practical and effective solution to safeguard valuable assets from adverse weather conditions.

By investing in quality Fabric Shelters and implementing proper maintenance practices, businesses can weather any storm and ensure their equipment remains safe and operational throughout challenging weather conditions.

The Impact of Weather on Equipment

Weather can have significant impacts on machinery and equipment, leading to various issues and challenges.

- Heavy Rain and Flooding: Water damage, rust, and corrosion of equipment components, malfunctioning electrical systems, contaminated fluids.

- Extreme Temperatures: Overheating and mechanical failures in high temperatures, reduced battery performance and lubricant thickening in low temperatures, affecting equipment functionality.

- Hail and Debris Impact: Dents, scratches, and potential damage to vulnerable components of equipment due to hail or wind-blown debris.

- UV Radiation: Fading, cracking, and deterioration of equipment surfaces, especially for equipment stored outdoors, due to prolonged exposure to UV radiation.

- Dust and Sandstorms: Infiltration of dust and sand particles into equipment systems, causing abrasion, clogging, and decreased efficiency, and extensive damage to sensitive electronic and hydraulic systems during sandstorms.

- Saltwater Exposure: For equipment located near coastal areas, saltwater exposure can accelerate corrosion and deterioration.

These weather hazards can increase the need for repairs, decrease resale value, negatively impact productivity and profitability, and pose safety risks. No industry is free from weather events, meaning mitigation strategies to protect equipment are needed across mining, industrial, agricultural, and various other industries.

To protect valuable assets, proper equipment storage and protection measures, such as weather-resistant shelters, maintenance routines, and early warning systems, are crucial. Additionally, proactive maintenance, including predictive maintenance to prevent overheating, can reduce downtime and extend the machine’s life, ensuring equipment remains in optimal condition even in adverse weather conditions.

The Need for Protective Shelters

Open-air equipment storage refers to the practice of leaving machinery and valuable assets exposed to the elements without any form of protective shelter. While it may seem like a convenient and cost-effective solution, open-air storage comes with significant limitations and risks. Harsh weather conditions, such as heavy rain, extreme heat, and dust, can cause water damage, rust, corrosion, overheating, and deterioration of equipment surfaces. Mechanical failures, malfunctioning electrical systems, damage and depreciation of assets, and reduced efficiency are common outcomes of prolonged exposure to these weather hazards.

To ensure the longevity and optimal performance of valuable assets, weather-proof shelters provide a superior alternative, offering protection from adverse weather conditions and safeguarding equipment from potential harm and costly repairs.

Using a dedicated shelter to safeguard valuable equipment offers numerous advantages, providing a secure and controlled environment to protect assets from the harmful effects of the elements.

A shelter can provide:

- Weather Resistance: A weather-proof shelter shields equipment from rain, hail, and extreme temperatures, preventing water damage, rust, and corrosion.

- UV Protection: UV-resistant shelters prevent fading, cracking, and deterioration of equipment surfaces caused by prolonged exposure to the sun’s harmful rays.

- Debris and Dust Protection: A shelter keeps equipment safe from debris impact, dust, and sandstorms, preserving sensitive components and ensuring optimal equipment efficiency.

- Humidity Control: A shelter with proper ventilation helps control humidity levels, preventing condensation and reducing the risk of corrosion and electrical issues.

- Longevity and Reduced Maintenance Costs: With a dedicated shelter, equipment experiences less wear and tear, reducing maintenance needs and extending its overall lifespan.

When considering a shelter solution to protect valuable equipment and assets, it is essential to prioritise key features that contribute to providing reliable protection. These include:

- Weather-Resistant Materials: Shelters made from durable and weather-resistant materials, such as high-quality fabrics or steel, can withstand rain, wind, and UV radiation without deteriorating.

- Waterproof Design: Shelters with a waterproof design and proper drainage systems prevent water leakage and protect equipment from water damage and rust.

- UV Protection: UV-resistant coatings on shelter materials protect equipment from harmful sun rays, preventing fading and deterioration of surfaces.

- Wind Resistance: Sufficient hold-downs and engineering that complies to relevant wind codes ensure shelters can withstand strong winds and storms, keeping equipment safe.

- Easy Access: Doors or clear entry points make it convenient to access and store equipment while maintaining protection from the elements.

By investing in a dedicated shelter from a reputable supplier, businesses can significantly increase the longevity and performance of valuable equipment, leading to higher productivity, reduced maintenance costs, and ultimately, greater returns on investment.

Types of Shelters for Different Weather Challenges

Steel/tin sheds are the traditional choice for equipment storage across many industries, particularly agricultural and industrial. These buildings are typically made of corrugated iron and are commonly used to store machinery, vehicles, tools, and other valuable equipment. They are reliable and can enhance a workplace as a permanent building addition. The durability of steel ensures that these sheds can stand for many decades with minimal maintenance required.

However, it is important to note that constructing steel sheds can be a time-consuming process. Factors such as obtaining planning permission, builders’ lead times, and groundworks need to be considered before the construction process begins. Additionally, steel sheds may have limitations, including limited natural light and poor ventilation, leading to a potentially humid and uncomfortable work environment, especially during the summer months when the corrugated iron can become hot.

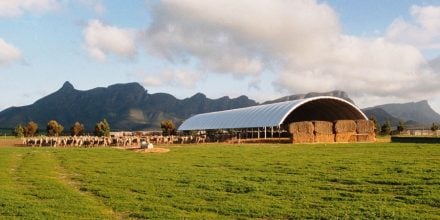

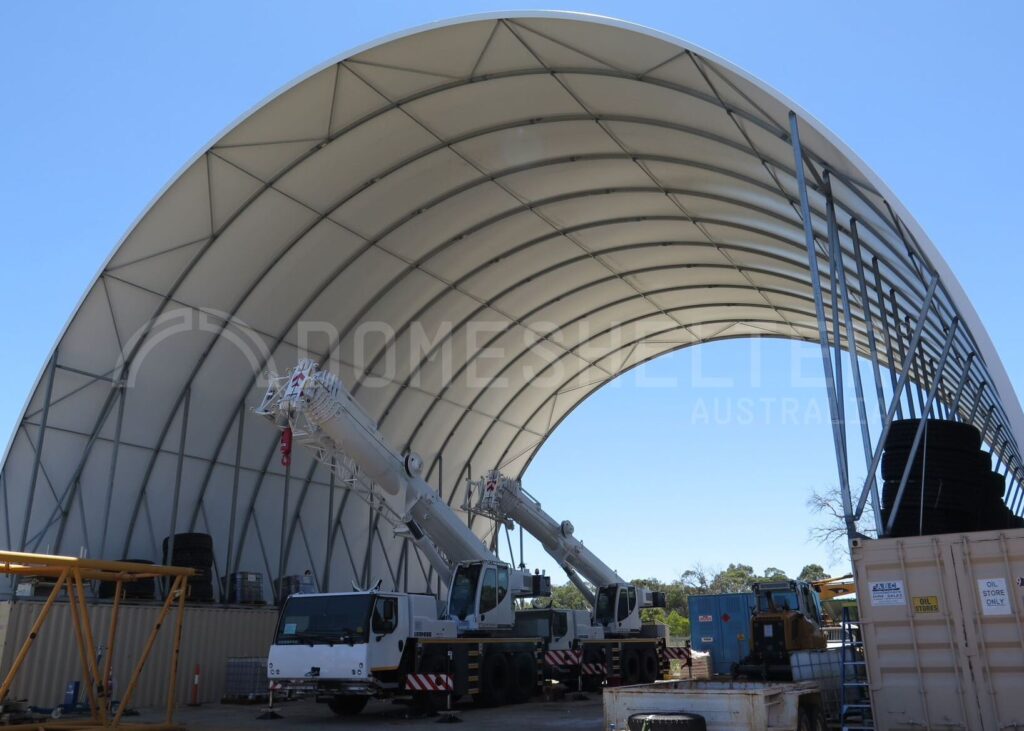

In the past two decades, fabric technology has made significant advancements, leading to the development of a modern Shelter Solution. Fabric Shelters, also known as container shelters, have emerged as a popular alternative to traditional steel sheds. They have gained widespread popularity due to their rapid installation process, ease of setup and relocation, and exceptional durability. These shelters are now trusted and utilised by some of the world’s largest mining, industrial, and agricultural companies.

Fabric Shelters can be customised to suit specific needs, with the option of being left open-ended or fully sealed with endwalls – endwalls can incorporate large equipment doors for easy access. These Shelters can be mounted on sea containers, posts, or concrete walls, and engineered to withstand extreme wind speeds, including Australian region D cyclonic winds. Their proven versatility and durability make them ideal in even the most challenging and harsh environments.

Fabric Shelters are an excellent solution for protecting valuable equipment from a wide range of weather elements. They are manufactured using heavy-duty fabric tarp and steel, able to withstand heavy rain, wind, and UV rays. These Shelters provide a weather-resistant environment, preventing water damage, rust, and corrosion. Rapid installation, flexible size range, short lead time, reduced environmental footprint and the ability to be dismantled and relocated offer advantages over traditional steel sheds that make them a favoured choice for many mining, industrial and construction clients.

In Conclusion

Weather hazards can pose significant risks to valuable equipment in various industries. Rain, extreme temperatures, hail, and other weather events can cause damage, reduce performance, and lead to costly repairs or replacements. Because of this, safeguarding equipment from adverse weather conditions is crucial to ensure the longevity and reliability of assets, minimise downtime, and maintain operational efficiency. Shelters play a critical role in protecting valuable equipment from the harmful effects of the elements. They offer a secure and weather-resistant environment, shielding equipment from rain, wind, sun, and other elements.

If you’re interested in how a durable, Australian-made Fabric Shelter can help you protect your valuable assets and improve your bottom line, try our free 3D Designer or get in touch with an experienced member of our team.