There was once a time when wooden barns were standard for sheds and shelters. With the advent of steel and corrugated iron, steel sheds became the new normal for workshops, warehouses and storage. Now with incredible advances in fabric technology and innovation in structural design, Shipping Container Sheds have become the shelter solution of choice by some of the world’s leading mining and industrial companies. In this article, we discuss the making of a Container Shed: what goes into getting your shelter solution from our manufacturing facility to your site.

What is a Shipping Container Shed?

A Shipping Container Shed (often referred to as Container Shed) is a new and innovative way to get shade and shelter to your site quickly. When compared to traditional steel sheds, they may also come at a smaller expense and provide the added advantage of quick and easy installation and relocation. Container Sheds can also leave little to no footprint when dismantled and relocated and can be stored in kit form for future use. They can be dismantled and moved across the site to cater to changing work needs, unlike permanent steel sheds, once installed.

What are they made out of?

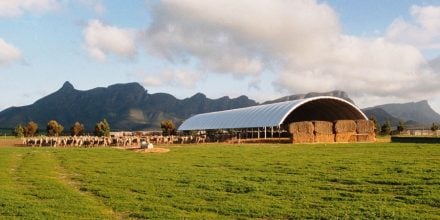

A Container Shed is an arched steel framework secured between two or more standard sea containers with high quality and heavy-duty fabric stretched over the top and firmly secured at the ends. The fabric structure can be from one to three containers high and the arched roof provides even greater height to accommodate some of the largest and highest equipment. While the length is just a matter of placing containers end to end for the desired length and continuing the roof structure.

How are Shipping Container Sheds transported to a site?

DomeShelter Australia’s Container Sheds are transported to some of the most remote sites in Australia and exported throughout the world as kits packed into sea containers. Up to 1000m2 of shelter space can be packed into one single container. Standard size structures can be made available to ship within just days of ordering and customised designs are also available to meet your specific needs.

See the DomeShelter Australia Specification Guide for details of standard sizes and configurations available.

How are Shipping Container Sheds installed once on-site?

The arched steel roof and fabric covering are fabricated in workshops and packed down into kit form for easy transport to site. Once on-site, installation takes as little as a few hours to a few days depending on size and complexity, and can usually be done by your team by following instructions supplied.

Clients may also like to take advantage of a skilled installation team from DomeShelter Australia or just a supervisor to support their team.

What can Shipping Container Sheds be used for?

Containers Sheds have a wide range of uses and have proven themselves in some of the harshest and remotest environments. Common uses include workshops for both large and small equipment, warehousing, small aircraft hangars, staff amenity areas, tyre change bays, refuelling stations, and garaging. Just about anything that requires shelter can be considered for a Container Shed.

They are generally used in situations that are more temporary, on land that is not necessarily owned by the shelter owner and when shelter is required to be installed quickly. So a typical case is when a company wins a contract and needs workshops installed quickly for a set time frame associated with the contract. On completion of the contract, the Container Shed can be dismantled back to kit form for relocation to the next site.

Speak with a DomeShelter™ consultant today

If you’d like to discuss your requirements and come up with the right shelter and storage solution for your needs, get in touch to speak with a DomeShelterTM consultant today.

Alternatively, you may wish to take advantage of the DomeShelterTM 3D Designer to create your shelter design in just minutes. No previous experience required. Visit our 3D Designer, to get started.