Wombat Junction, a critical hub in Rio Tinto’s Pilbara railway network, has long been a cornerstone of the company’s iron ore operations. Located north of Tom Price, it serves as a pivotal point where rail lines diverge to connect mining sites with major port facilities.

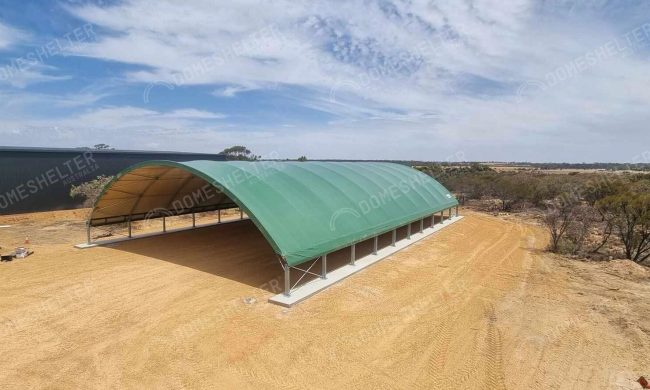

With operations expanding and the demands of this junction growing, the need for an upgrade in infrastructure became clear. Rio Tinto partnered with DomeShelter Australia to deliver a custom shelter solution design to improve their site functionality for critical rail tasks and safeguard their workers from the unrelenting Pilbara sun.

The Challenge

Rio Tinto required a durable and weather-resistant shelter to facilitate train maintenance and washdown operations while ensuring worker safety in the extreme Pilbara climate. The project at Wombat Junction posed a unique set of challenges for the DomeShelter Australia team:

- Preexisting Infrastructure Limitations

The shelter had to be integrated into an irregularly shaped concrete slab at a critical rail convergence point. It needed to span two rail lines while being tightly positioned against a third, significantly limiting placement options.Rio Tinto’s regulations required external walls to remain at least 3 metres from the nearest track, while internal spacing had to prevent “crush points” where workers maneuvered around equipment.

- Intense Heat

With no existing shade or climate control, workers performed maintenance in temperatures often exceeding 50°C. Their tasks involved specialised equipment used to reshape rail domes, a critical process that became increasingly difficult under such conditions. - Safety and Fire Risks

Site policies prohibited on-site welding due to extreme heat and fire hazards, and also restricted workers from working on the active line side of the shelter or on top of the containers for installation and maintenance. - Tight Deadlines

Rail operations followed tightly controlled schedules, meaning the shelter had to be installed within brief shutdown windows to avoid costly delays and disruptions. - Project Management

Rio Tinto required a turnkey solution, seeking a partner who could manage the entire project from start to finish, including liaising with stakeholders, coordinating contractors, and ensuring compliance with their strict safety and operational standards.

With summer temperatures in Tom Price quickly approaching, it was essential that they have a solution that could be engineered, shipped and installed ahead of the extreme heat.

The DomeShelter™ Solution

DomeShelter Australia provided a turnkey shelter solution at Wombat Junction, addressing operational and environmental challenges with seamless integration into Rio Tinto’s existing infrastructure.

Key challenges—such as proximity to the railway, fire safety restrictions, and limited installation access—were overcome through innovative engineering and project management. DomeShelter implemented a non-welded bolt-on system to meet fire risk requirements, developed a raised plinth system to accommodate the existing concrete slab, and introduced safe tarp installation methods to navigate restricted access near the rail line.

DomeShelter Australia managed the project end-to-end, coordinating directly with Rio Tinto and contractors to ensure a smooth execution of the project while also minimising operational disruptions.

Key Features:

Dimensions & Design

- Width: 22.7m | Length: 48.7m | Apex Height: 7.5m

- Engineered for Wind Region A with container post-mounted design.

- Constructed with hot-dip galvanised steel and Armourtex® 400gsm fabric, ensuring longevity and durability.

Integrated Features

- Modified 40ft containers with roller doors, split-system AC recesses, and electrical setups for workshops and storage.

- Heavy-duty sliding curtain doors and side blinds for accessibility and ventilation.

- LED high-bay lighting and HVLS ceiling fans for optimal visibility and climate control.

Comprehensive Site Services

- Delivery of all materials to Wombat Junction.

- Construction of footings, foundations, and the DomeShelter™ Structure.

- Complete project oversight by a dedicated team from DomeShelter Australia.

Outcomes

Custom Engineering for Complex Requirements

- Engineered to meet Cyclone Wind Region A standards, ensuring resilience in harsh conditions.

- A custom plinth footing system accommodated the irregular concrete slab while allowing effective water runoff during washdowns.

Safety-First Installation Methods

- A pre-drilled, bolt-on mounting rail system replaced traditional welding, eliminating fire risks.

- A static line system enabled workers to safely access the top of containers for tarp installation.

- A pull-through system allowed the tarp to be secured from within the shelter, eliminating the need to access the restricted side near a major crush point.

Integrated Workshop Containers

- Three high-cube shipping containers were modified for fabrication and maintenance.

- Features included roller doors, power outlets, lighting, and recessed air conditioning units for compliance with site standards.

- Electrical fit-outs met Rio Tinto’s strict mining requirements, including lockable switchboards and certified circuitry testing.

Optimised Workflow and Safety Features

- Sliding doors and well-placed access points improved equipment and personnel flow while minimising crush points.

- Enhanced ventilation and thoughtful design created a safer and more comfortable working environment.

Seamless Project Coordination

- DomeShelter Australia managed the project end-to-end, from design to installation.

- Liaised with Rio Tinto stakeholders to ensure compliance with site requirements.

- Coordinated specialised contractors and adhered to tight delivery schedules to prevent disruption to rail operations.