Hold-downs or anchoring solutions are an integral part of a Fabric Structure, ensuring durability and the safety of the Shelter and those working under it.

They can also often be an overlooked or forgotten element, with customers not realising they are necessary and wondering how they fit into the cost and installation process for a Shelter.

This article explains what hold-downs are and why they are important for all Fabric Structures.

So What Are Hold Downs?

A hold-down is a device or piece of hardware that is installed to prevent a Shelter from lifting off its foundation. They can also be known as tie-downs, ballast, foundations, or sometimes anchors.

Hold-downs are a key element of a safe and durable structure.

How Do I Know What Hold-Downs I Need?

There are a range of hold-down options to suit different shape and size structures. The following questions can help determine what hold-down option that will likely be best suited to your Fabric Structure:

- What size is the structure?

- What is the Structure’s configuration? E.g., Double stacked? Containers in? Endwalls?

- What design parameters are in place? e.g., Wind Region?, Terrian Category?, Importance Level?

- What are the site conditions? e.g. corrosive environment? Wet environment?

- What is the soil type? e.g. Cohesive, or non-cohesive? What is your soil bearing pressure?

- Project duration? Long-term or short-term? Is re-usability a factor?

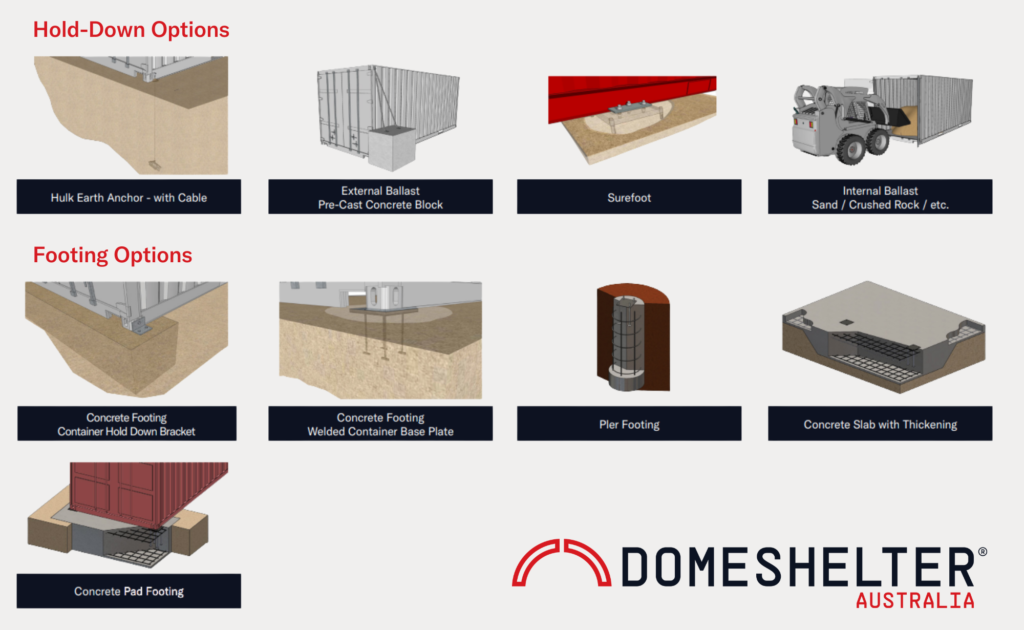

What Different Hold-Down Options Are There?

Ballast

Heavy material, such as gravel, sand or any waste soil used to achieve the required hold-down capacity for the structure, as specified by the engineer. The ballast is loaded inside the sea containers to anchor the Fabric Structure.

Pre-Cast Concrete Blocks

Large, external, pre-cast concrete blocks that are positioned around the perimenter of the containers and secured to it. Again, the capacity of the blocks need to be specified by an engineer

Concrete Strip Footing

An in-ground footing, cast onsite to the engineer’s specifications, that is designed to be fit-for-purpose to suit each individual Shelter. This connection can be either bolted or welded to suit the application

Concrete Pier Footing

Another in-ground footing, cast onsite to the engineer’s specifications, that is fit-for-purpose to suit each individual Shelter. This option uses less concrete however requires a compatible soil type

Concrete Slab Thickening

Using the infrastructure of a concrete slab between the containers, a thickening of the slab under the columns or ends of containers to specified requirements from the engineer, keep civil works in one package

Earth Anchors

Anchors drilled or driven into the ground as analternative to concrete. These can be found in many different forms and require specification from the manufacturer, to suit the wind loading from the Shelter

What is the Cheapest Hold-Down Option?

Ballast is generally the most cost-effective Hold-Down for Fabric Structures, especially where ballast material such as gravel or fill is already available on-site.

It’s important to remember that where ballast is used, the containers will not be available for storage or fit-outs such as office space.

For some Shelters, the ballast option cannot be used, due to a combination of the wind loadings on the Shelter and the capacity of the containers.

What is the Quickest Hold-Down Option?

For any time-driven projects, your best options might be Ballast or Earth Anchors. Please note the Earth Anchors may require professional installation.

Temporary vs Permanent?

Your project might have a duration of 10 years, or it might be 10 months. Either way, your Shelter needs to be secured, but the intended duration may help establish your best suited hold-down option.

Suggested options for temporary hold-downs are:

- Ballast

- Earth anchors

- Pre-cast concrete

Suggested options for semi-permanent hold-downs are:

- Concrete strip footing

- Slab thickening

- Pre-cast concrete

- Pier footings

What are the Most Environmentally Friendly Hold Down Options?

Ballast has little to no resulting impact on the surrounding environment and can allow the Shelter to be removed with little impact on the surrounding landscape.

Concrete pre-cast blocks are another option where the ground is not disturbed and they can be packed up and taken away for reusing again.

How Can DSA Help?

You can engage DomeShelter Australia’s support by using 3rd party engineers to provide specific hold-down requirements and designs for your project. If you wish to engage this service, our team designs to your specified hold-down option, while taking into account your site location and, in some cases, even geotechnical data.

A DomeShelter™ Consultant will walk you through the hold-down options for your specific project and ensure any questions are answered.

It’s important to work with a company that provides a thorough consultation and design process, as well as in-house engineering, to be sure that all the boxes are being checked and you are being supplied a safe and durable Shelter.

If you have any questions about DomeShelter™ Structures or would like to enquire about a Shelter, get in touch today or try our free 3D Designer.